item

item

PRODUCT INFORMATION

Description

Details

Extras

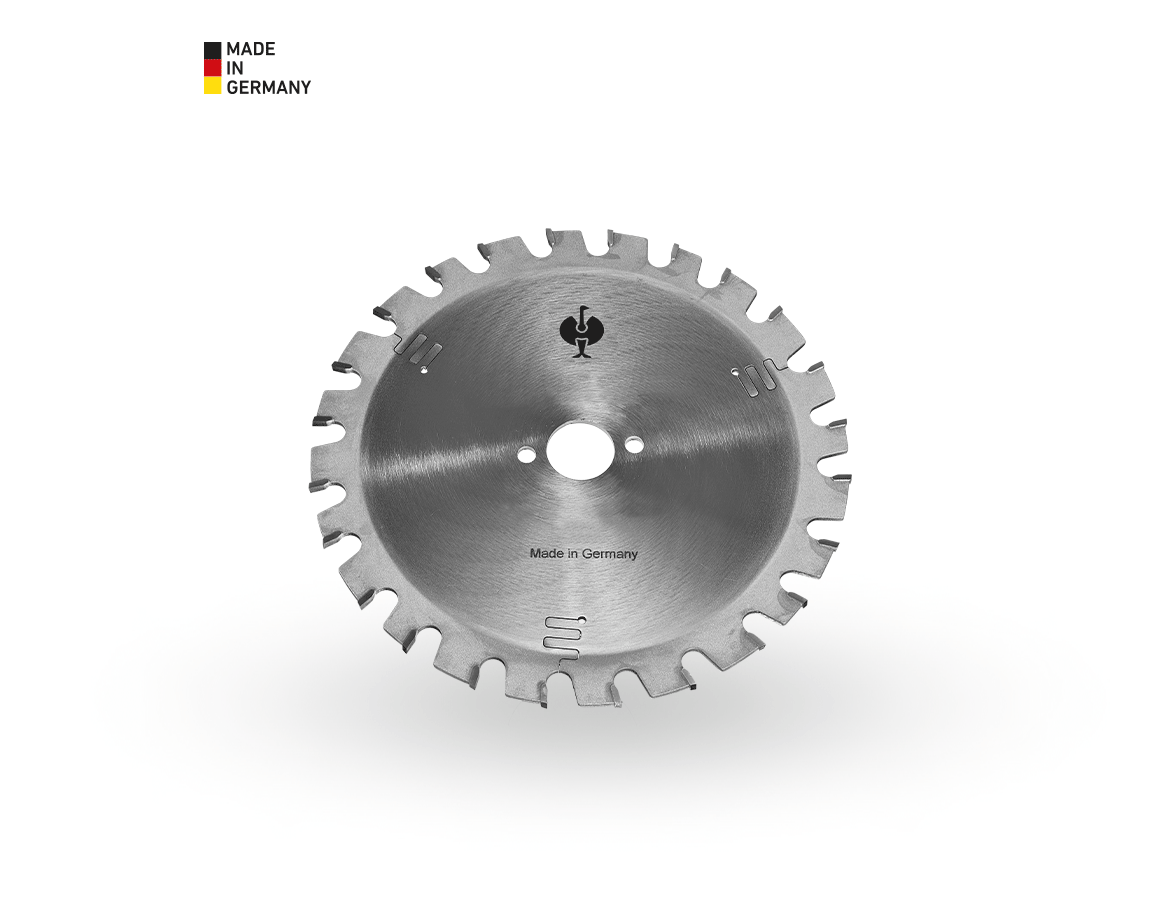

Ground flat, polished, precision-ground teeth, for manual and table-top circular saws.

Precise boreholes: Increase the true running accuracy of the circular saw blade.

Precise boreholes: Increase the true running accuracy of the circular saw blade.

Application: Wood with inclusions (caused by tight nails), wooden formwork, aluminium profiles, soft iron, light bricks, metal-sheathed MDF boards, sandwich boards, hard plastics and thermo elements.

Ø x thickness x bore mm

160 x 2.8 x 20

160 x 2.8 x 20

Teeth number/form

24/SWZ

24/SWZ

Made in Germany

Additional information

Purchase advice

Mix & Match

Language selection

All prices plus shipping

on orders below 1 250,00 kr.

All prices plus VAT

plus shipping

on orders below 1 000,00 kr.